Streak Camera : General measurement overview

Switch on

- lasers

- computer

- Switch all streak camera electronics on. HP amplifier should normally be on 20 dB, but sometimes possibly on 40 dB.

If laser is mode-locked and the Streak camera gets triggered, the little light at the side is green.

Trigger photodiode optimization ?

- before unplugging, switch of bias.

Single sweep unit : with pulse picker (2 MHz ?). Longest decays.

Synchro sweep unit : at 76 MHz. Only for very fast decays.

Synchro : fastest timebase (1) warms the streak camera, so it needs quite some time to stabilize, for stable time base !!

Synchro scan timebase 1 : Do alignment (lateral movement, first lens) not in focus mode, since this will cool down the streak camera.

[ Keeping the streak camera all the time in Operate mode is fine. It will keep warm ]

In range 1, the meter on the streak camera (indicating the reflected power) should be as low as possible. Use the pot-meter on the front to tune the impedance.

Top box is for Synchro, Bottom for Single. All delays can be computer controlled.

Shutter before streak camera (red arrow)

- Left : closed, top 0 position, to the right : open.

- Max open at right 90 degrees.

- NB: vertical stripes in spectrum are caused by dust particles.

- Best practice to remove dust particles on slit : open 180 degrees, then back to wanted position.

Align general optics

- Close slit of Mira until laser is just visible. Beam is weakened.

Hollow fiber

- Most of the time the light directly from the Mira is used (fast decays). If needed the light behind the pulse picker can be used (slow decays).

- Best pump wavelength : 820 nm. 4.6 watt is enough.

- Align: use 35 mW (max 50 ?) until it works, then +/- 90 mW for better aligning.

[ it should work @ 50 mW, but maybe not yet @ 35 ]

- Max entry power : 1 W (?).

- Normal use e.g. 70 mW.

- Alignment : use IR-viewer to see the light passed (most of it is IR), which falls on piece of paper.

- Adjust mirror just before variable OD-filter for max throughput. The more white, the better. Very sensitive.

- Put interference filter after fiber (546 nm) & RG1 filter (absorbs IR).

90 mW in : 104 microW out (green)

74 mW in : 44 microW out (green)

[17 mW passes through the fiber (?) ]\ \

Synchroscan

- 165 ps

- 800 ps

- 1450 ps (delay ~ 8840 ps)

- 2200 ps (delay ~ 9600 ps)

going fro 4→1, above threshold drops

Software

HPD-TA 32 program [NB : This is for the old program ]

- On start, select IC-PCI+AM-DIG & C4742-95 at 1

- Config : c:\program files\HPDTA32\digital.cnf

- F8 is panic button : all shutters close etc.

Time range : 1 = fastest, 4 = slowest.

Focus : no time-spread. so all light falls on center of mct. Potentially dangerous !! If focus-mode, a little red light shows on side of streak-camera.

Focus-time-over : 5 minutes. Focus auto shuts off after 5 minutes.

The shutter of the streak camera is behind the entrance slit.

MCP gain : 0-63. Start with 10-20. For Single Photon counting : use 63.

Normal delay time : 9060 ps. Enter box, use up/down arrow to change (moves life image up/down).

Show signal Press “Acquisition”, Live, Live.

“Use auto streak shutter & MCP gain ?” : No. (yes uses previous settings & opens shutter).

ROI: select calibrate.

Button bar at the right, select

- Show or hide the quick profile

- Show or hide the ROI I/F window

- Select a rectangular ROI

ROI window : select calibrated

Menu analysis : select Profile

Menu

- Setup, scaling

- Set spec calibration

- set grating 40

- Pixel location +- …

- Assign scaling

- System scaling setup :

- [x] Assign scaling tho image

- ROI GetH

Photon counting

- First : Setup : determines threshold [ ~ 80 = threshold]

LUT : left 30, right 60-70

Chromex monochromator

Most used grating : 40.7 micrometer.

Calibrate always when switched on again.

Calibration lamp before monochromator (546.08 nm peak ).

Life acquisition mode, slit monochromator: 10 micron, MCP gain 10, slowly open shutter.

Resolution monochromator is 0.7 nm.

Adjust calibration: ???

example

pixel wavelength [nm]

868 539.6

875 543

878 546

(so about 0.7 nm / pixel)

Best camera slit value (the one with the red arrow) : 20 micron (see top).

Less: light loss, More: more signal but time resolution loss.

Alignment after fiber:

Insert 1 mm cuvette with Rhodamine 6G or so.

Optimize the 2 microscope lenses by: ???

Final measurement : Photon counting.

Select a small area which is most crowded. …max 5% or so. Means 5% of the pixels contains a photon.

Exposure not smaller then 56 ms. Otherwise to much loss for read out

Threshold: make image with 1000 exposures. run Setup. threshold around 80 is fine.

Exposures e.g. 10000 = 30 minutes

LUT

- Don’t forget to push the ‘*’ on LUT for auto set. Auto goes minimal to 16, but can go to 4 with arrows.

Change sample

- Only adjust lateral translation of the lens closest to the sample.

- Clean cuvettes on the outside

Cut-off filter before monochromator

OG 570

Synchroscan

Little meter shows the amount of bounced signal due to impedance mismatch. This can cause the streakcamera to stop. Minimize : there is a little hole to the left of the front, which gives access to a variable capacitor.

One of the gratings inside the monochromator (300, or maybe 100 lines/mm) is replaced by a 2400 lines/mm !!!

The lens system between the monochromator and the streak camera is made of quartz. For different wavelength it might be necessary the change the focus of this system a bit (big ribbeled ring), since it is not completely achromatic. And if focus is not good, so is the time resolution. There is also a lense between the streak-camera and the ccd-camera : loosen the screw, and turn the ring between the streak and ccd camera, for best focusing.

Switching of Synchroscan to SingleSweep unit

- Remove trigger cable from unit & remove smc plug.

- Remove Synchroscan unit : push buttons and rotate backwards. The rotation pushes the unit out. Be carefull to to move the streakcamera itself. Maybe do 1 button at a time.

- Enter SingleSweep unit : in principle the unit will be pulled in by rotating the knobs. A little pushing might help. Be carefulll not to move the streak camera. Be carefull not to damage the pins of the connectors. Check afterwards if the unit is really pushed in.

- Output of HP amplifier to input C4792 (single scan delay box).

- C4792 StreakOut output to SingleSweep unit.

- If the laser is modelocked, both the ModeLock Clock and the External Trig on the C4792 unit are green. (1 is the modelocked frequency, 1 is the signal from the pulse picker).

- In HPDTA program : start, Profile, Load profile : “c:\programdata\Hamamatsu\HPDTA\SingleSweep.hwp”

- In C4792-01 menu : Trig.mode → Dump Mode !!

- Dly1 dumpmode : coarse delay (in ps). Holding shift (?) while arrow up goes faster

Dly1 dumpmode : fine delay (ps) : delay is also shown on C4792 box

Options, Devices, Delay generator : here you can choose which settings are saved to disk on leaving the program

SingleScan unit

TimeBase -- Delay

100 ns - -300 ns (?)

50 ns -- 390 ns

20 ns -- 460 ns

5 ns -- 500 ns

The delay also depends on the height of the laser beam above the transduces of the pulse picker.

Playing with the delay, you can see 2 time traces. One for the forwards sweep and one for the backwards sweep. Use the one where the increasing time goes from top to bottom.

OG570 / OG590

OG570 transmits a little bit of the green light produced by the fiber. Use this to align the signal, if no fluorescence can be found.

Triggering

The fastest synchro-timebase is the most sensitive for the trigger signal.

If the red “uncal”-led (close to the impedance mismatch meter) glows, there might not be enough light falling on the trigger photodiode.

According to the manual : increase the amount of light, so the triggering happens earlier. If it starts triggering later again, it’s just to much light. Put it at the earliest triggering moment.

Purging & cooling of Mira

From the manual :

Cooling water :

- max temperature : 15 C

- min flow rate : 0.3 liter / minute

- pressure : 2 bar

purging with dry N2 :

- Initial purge : 10 CFH

- Later purge : 2 CFH

Purging is especially recommended for operation above 870 nm.

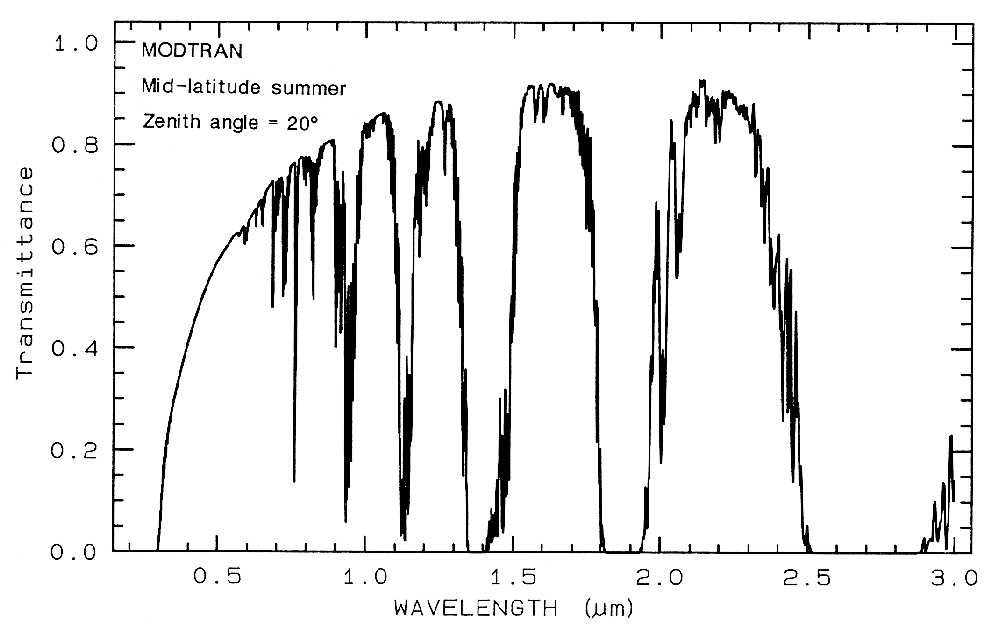

Strong water absorption : between 920 and 970 (high velocity purge needed for several hours to get below 5%).

Other water absorption's : around 761 +/- 5 nm and 820 +/- 5 nm.

Take a look at the aborption spectrum of water in the atmosphere.

From this absorption spectrum, it follows that above 890 nm, the water absorption begins !!

Clean the optics of the Mira

- Always close shutter of Verdi, before cleaning a mirror.

- Use Acetone PA for cleaning & hemostat. Clean every optics once.

- Remove tube between Verdi & Mira. Clean output mirror of Verdi & input Brewster window of Mira at the outside.

- Reinstall tube

- Remove left top side : the little things at the sides flip up as wings, and can be used to lift the cover. The cover might be a little sticky. Lift wing, and push with other fingers on the laser, between the edge of cover and laser.

- Also remove the side panel, facing the Verdi. Push button downwards.

- Clean all optics.

- To clean the crystal, remove the little tubes. Be careful not to scrape the crystal with the left tube.

- To clean the lyot filter, remove it first.The small 1/16“ screws releases it. Only 1 way to reposition it.

- The left side of the dichroic mirror can be reached, without removing the mirror.

NB : after opening the Verdi shutter again, the Mira stays for several minutes on monitor=0.68. Then the monitor very slowly starts to rise.

It takes at least 5 minutes, before it is at it's maximum.

Realigning is hardly needed.

According to Ben, the Mira is cleaned at most once a year.

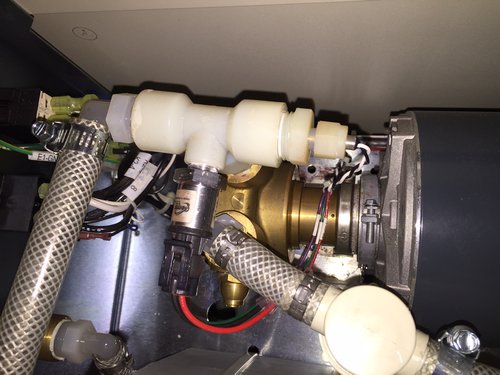

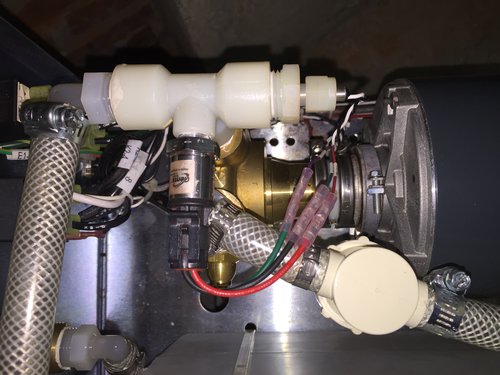

Replacement of the pump-head of the Lytron chiller

The laser has done 8575 hours. This is the first replacement.

- Unscrew right temperature (?) sensor, and pull it out.

- Remove front pressure (?) sensor (it's just a plug).

- Disconnect left tube

- Disconnect right tube (the connection on the plastic L-connector could not be loosened, to disconnected it after the little filter (?).

- Disconnect the pump-head from the motor.

- Unscrew the 2 plastic connectors from the pump-head.

- We reused the 2 plastic connectors. Reapplied 1 or 2 windings of teflon tape.

- Reassemble. This time we also used the 'break'-connector. *It was broken for a year, and the pump head was since used without it.

[ The plastic ring between the pump-head and the motor is needed if this 'break'-connector is used ]

We did not check the pressure generated by the old pump-head.

The original specifications sheets of the legend indicated the pressure was 86 PSI.

Pressing the button with the arrow on the Lytron chiller shows the pressure in PSI.

Turning the relieve valve on the pump head clockwise (2, 3 rotations maybe, goes inwards) we increased the pressure from 55 to 85 PSI. The pressure sort of displays anything between 80 and 89 though, between each reading (per second).

Spare parts :

Situation before :

Situation after [Note the extra spacer ring between the pump head and the motor] :

Water absorption in the atmosphere

This is actually a modelled spectrum, of the entire atmosphere (but most of it is water).

From : http://speclab.cr.usgs.gov/PAPERS.refl-mrs/refl4.html

760 nm is O2

2000 nm is CO2

2060 nm is CO2

The rest is water

Another nice reference : http://irina.eas.gatech.edu/EAS8803_Fall2009/Lec6.pdf